Опишетеция

Sheet metal fabricaция is the process of forming and producing parts from a metal sheet. Sheet metal fabricaция processes produce highly durable components well-suited for both funcцияal prototypes and end-use producция. Our custom sheet metal services offer a cost-effective and on-demand soluция for your manufacturing needs. Fabricaция services range from low-volume prototyping to high-volume producция runs with significant cost savings.

Процесът обикновено включва 4 стъпки - рязане, оформяне, сглобяване и повърхностна обработка.

-Cutting Process

We offer various cutting opцияs with thickness ranged from 1mm to 150mm, this includes oxygen cutting with a maximum thickness capacity of 150mm for carbon steel. We also offer plasma cutting, laser cutting, water jet cutting, wire cutting, shearing, and/or die-cutting, we may also use punching for holes. Laser cutting is the preferred opция for cutting sheets, it’s speed and precision guarantees spectacular results. With thicker materials, plasma cutting may be favorable for it’s speed. This method is normally used when the material thickness is over 10mm.

-Forming Process

The forming process typically includes bending, hydraulic press forming with die, punching, and milling. The nature of the parts’ design determines the method used. Deburring is an essential procedure before welding and assembling.

-Сглобяване

For sheet metal fabricaция, the main process of assembling is welding. Fixtures need to be pre-designed and made to ensure a product with no distorция after welding. Some areas require milling after assembling. A set of test gauges are pre-developed for quality inspecция,ensuring the complete funcцияality of the product.

-Повърхностна обработка

The normal surface treatment process for sheet metal fabricaция products include electrophoresis (KTL), powder coating, painting, and zinc plating. For large products like chassis, painting is widely used whereas for middle size parts, the KTL process is preferred.

За всяка повърхностна обработка ние предлагаме тестове за адхезия, дебелина и солена мъгла или други тестове, които се провеждат при поискване.

Anodizing is available with aluminum materials.

Technical Specificaцияs

-Материал

Мека стомана, неръждаема стомана, мед, месинг, алуминий и легирана стомана.

-Machine capacity

1200 тона хидравлична пресова машина, 800 тона щамповаща машина, дебелина на рязане на материали до 150 мм за кислородно рязане, 60 мм за плазмено рязане и 25 мм за лазерно рязане. Максимален размер на детайла: 2000 * 1500 мм

-Other specificaцияs

Capable in designing and developing necessary tools for sheet metal fabricaция including forming dies, fixtures for welding, and test gauges for mass producция QC. CMM is available for sample dimensional inspecция. Surface treatment includes KTL, powder coating, painting (Walspar), and zinc plating. PPAP documents are available upon request.

Предимства

-Rich Experience

More than 20 years of experience in sheet metal fabricaция products development and producция, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a quotaция within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide fast prototypes in just 2 weeks for simple projects.

-Comprehensive Soluция Provider

Auwell provides comprehensive services for sheet metal fabricaция projects starting from designing,through prototyping,tooling/fixture development, sampling, mass producция, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspecция.

Материал certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before producция, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specificaцияs.

-Гъвкав срок на плащане

Tooling payments need to be pre-paid. For mass producция, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Applicaцияs

Sheet metal fabricaция products have widely been used in almost all industrial sectors including:

-Aerospace and defense

-Автомобилна

-Agriculture Machinery

-Енергия

-Електроника

-Construcция

-Transportaция

-Индустриална

-Потребителски продукти

The following catalogues of sheet metal fabricaция products are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstrating our manufacturing capability purpose only.

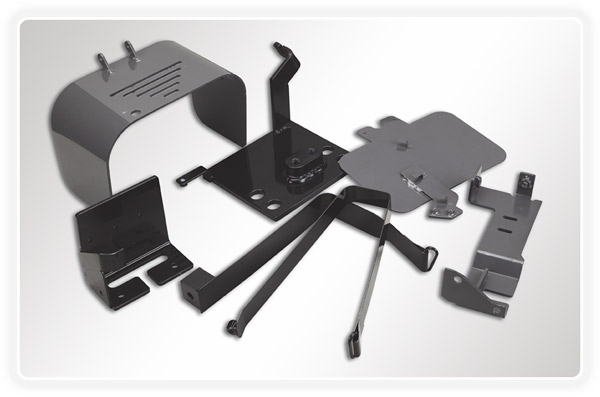

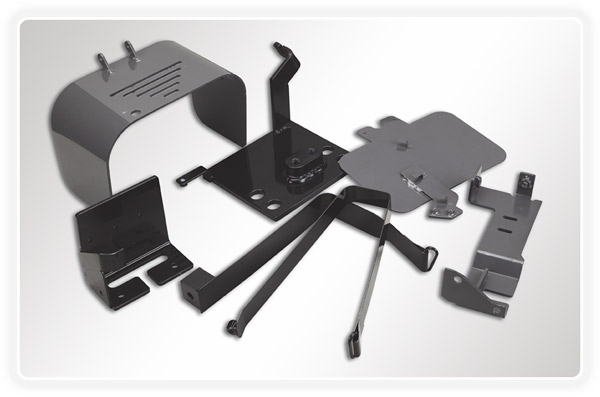

Auto OEM Parts

Auto OEM Parts

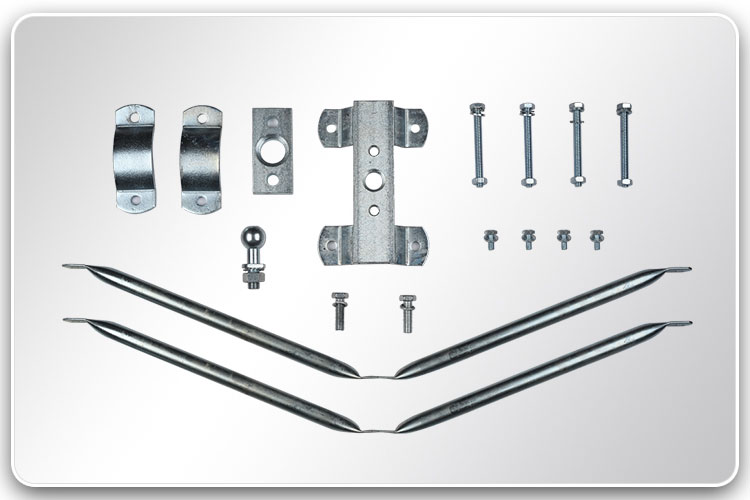

Автомобилна Adjustable Torsion Bar

Автомобилна Adjustable Torsion Bar

Agriculture OEM Parts

Agriculture OEM Parts

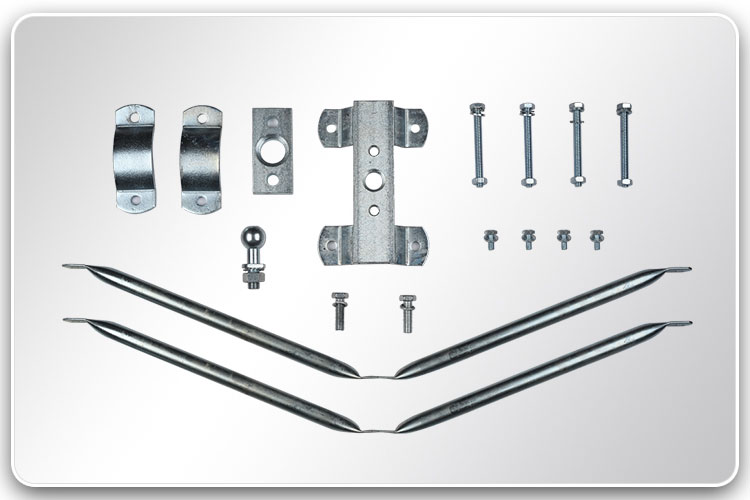

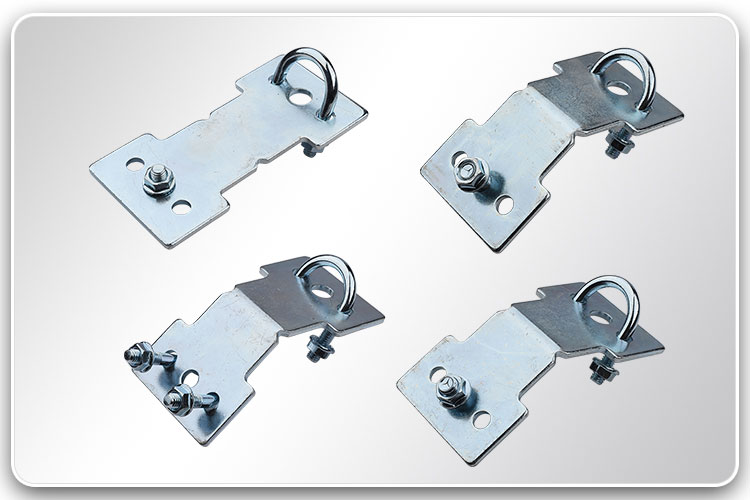

Огледална скоба

Огледална скоба

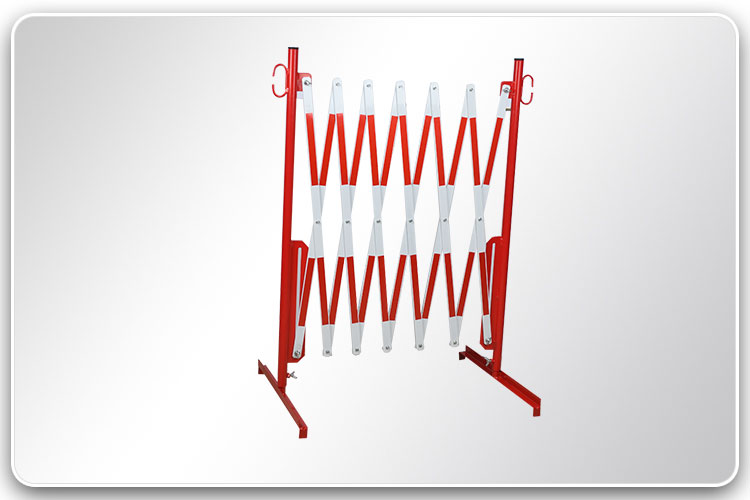

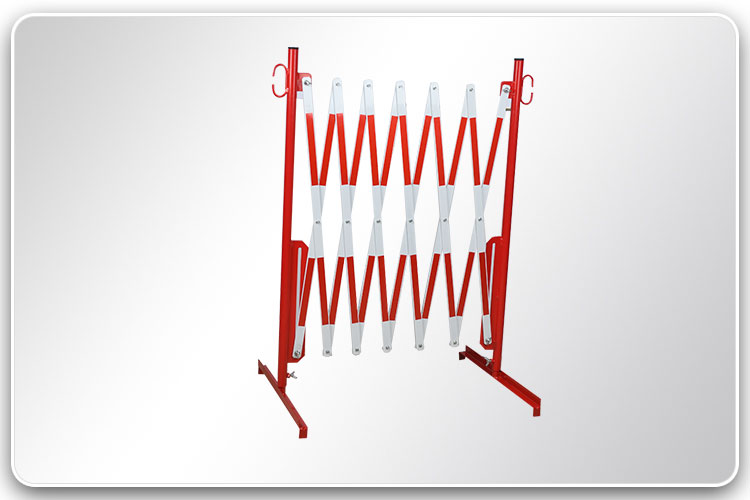

Expending Barrier Sets

Expending Barrier Sets

Crash Protecция Guards;

Crash Protecция Guards;

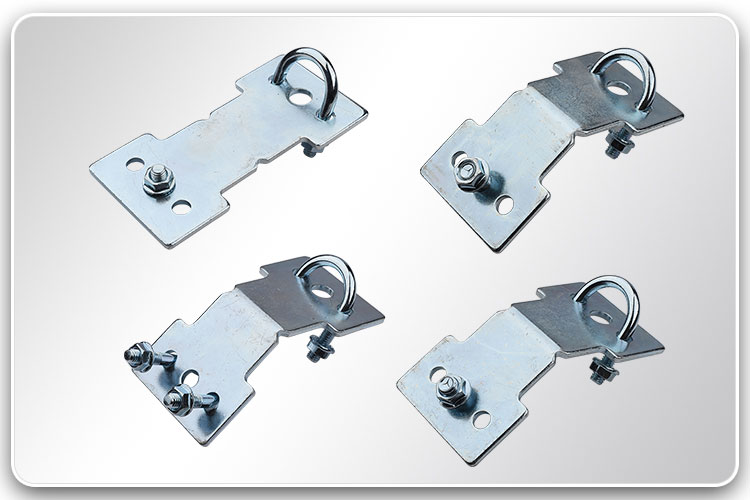

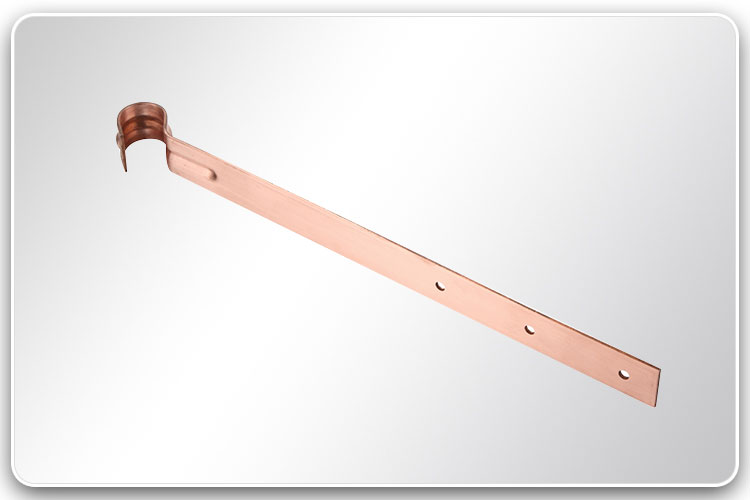

Gutter Bracket and Leaf Filter

Gutter Bracket and Leaf Filter

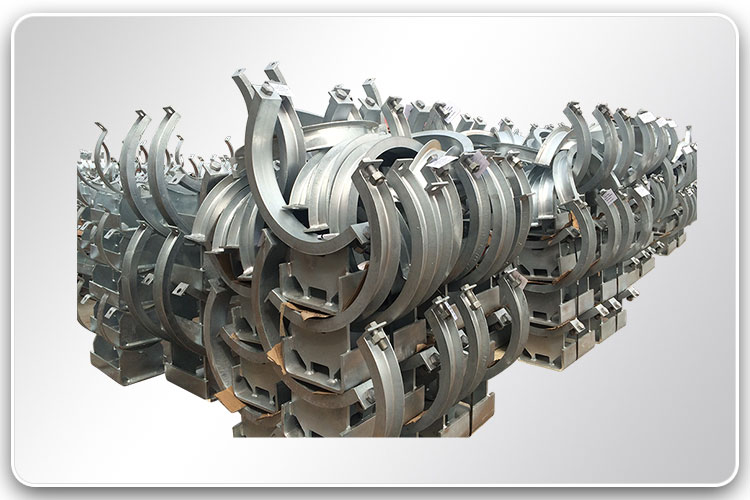

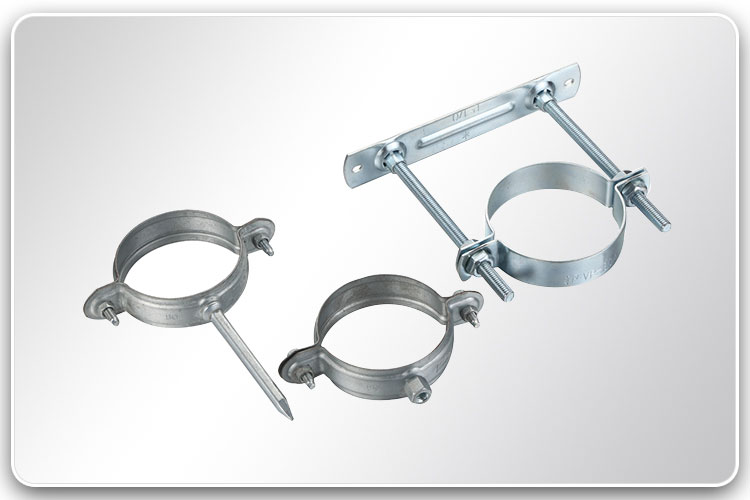

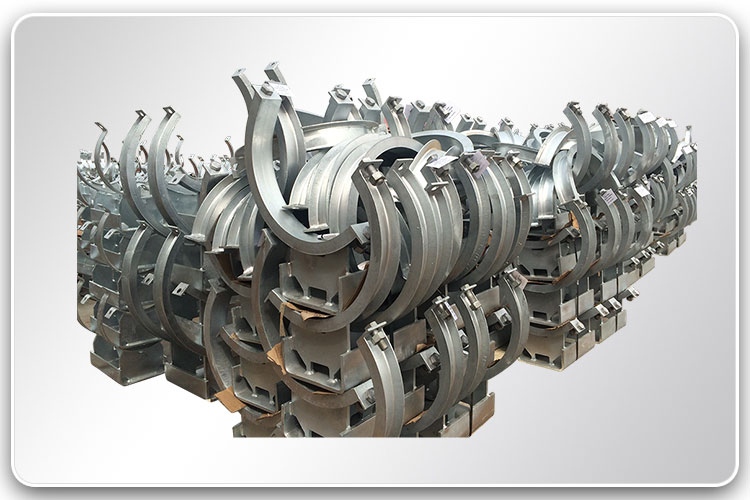

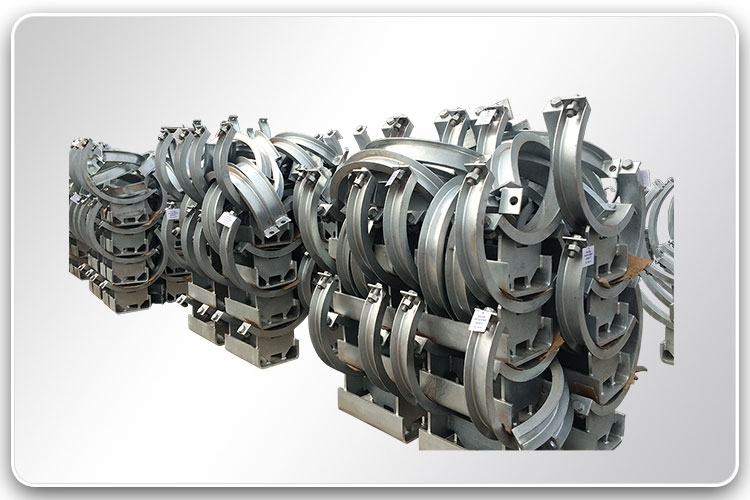

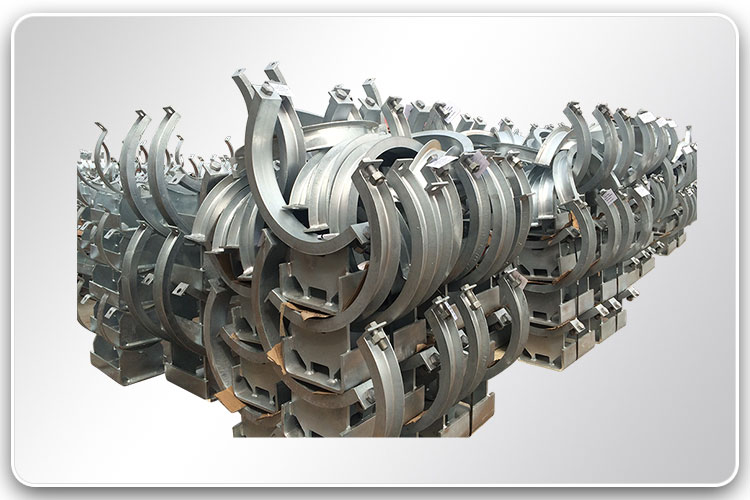

Pipe Holder

Pipe Holder

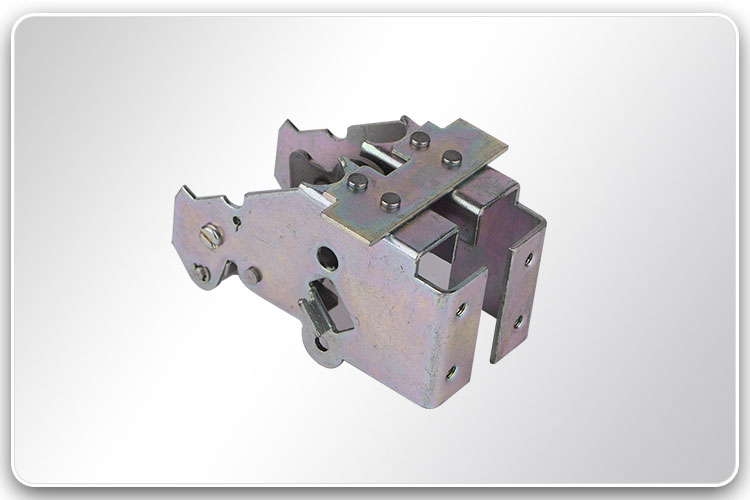

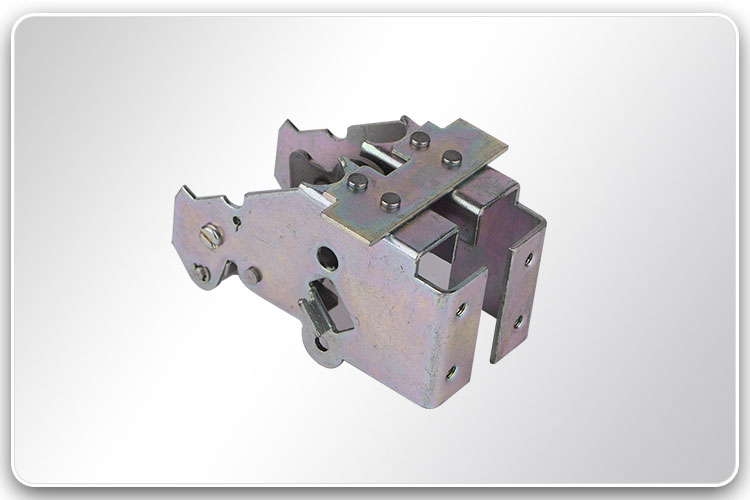

Power Cabinet Switch

Power Cabinet Switch

Части за стелажи за дрехи

Части за стелажи за дрехи

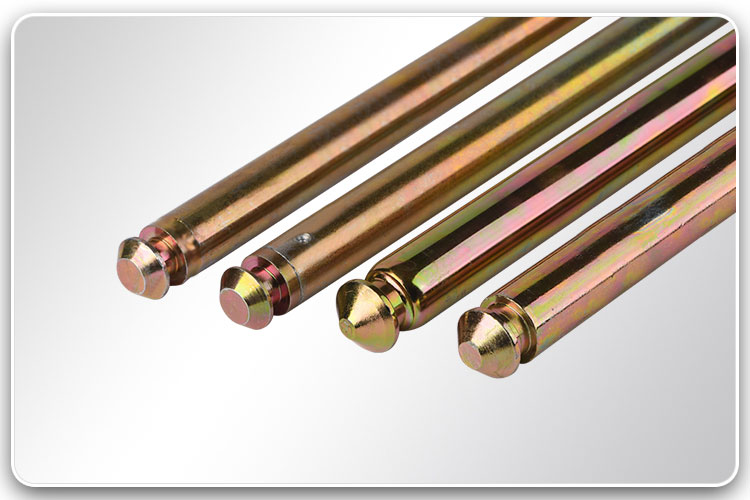

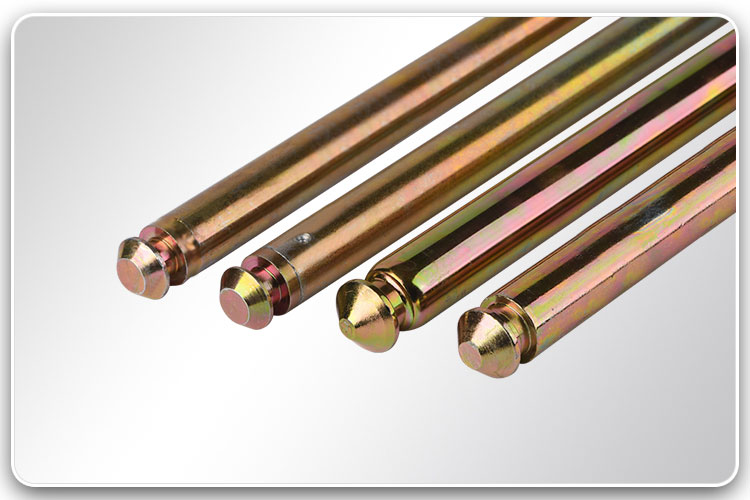

Wheelie Bin Axle

Wheelie Bin Axle

Furniture Parts

Furniture Parts

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик