Описание

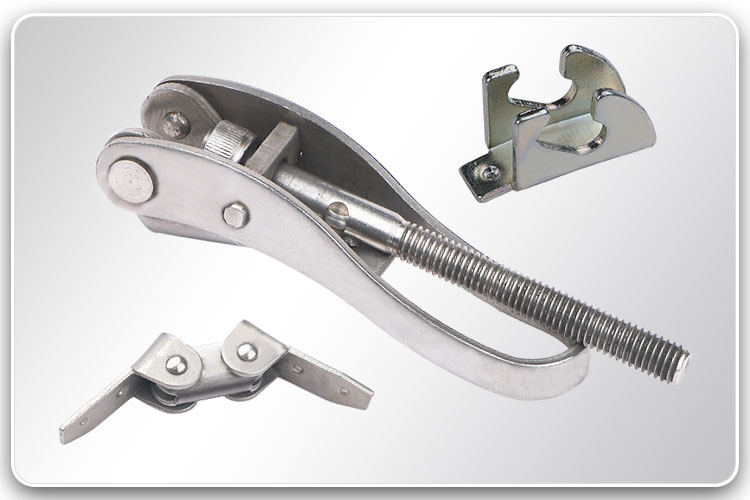

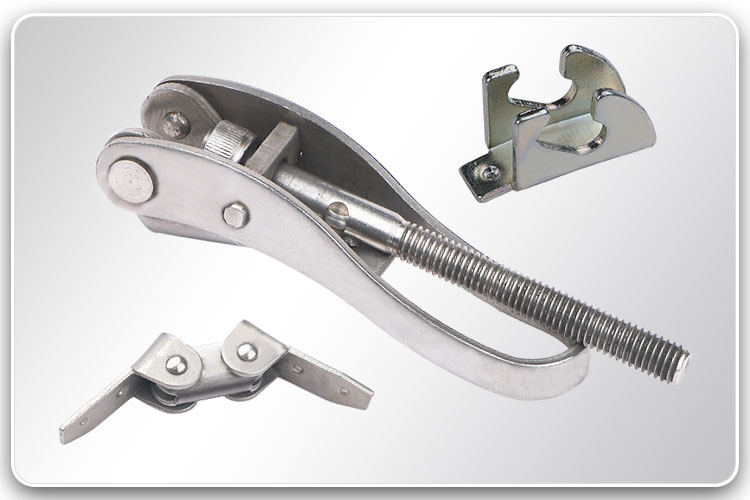

Turning Parts for Spannring are the essential components for clamping ring products. If the closing side of the ring is jointed with saddle and bolt, one clamping ring set consists of generally 4 turning parts. Φ12mm and Φ14mm are the most popular diameters. A set of clamping ring consists 2 of turning parts for the clamping rings, for Φ12mm diameter, one with 6.5mm section hole and M6 thread hole for another, likewise, Φ8.5mm holes and M8 thread holes for Φ14mm turning parts for the clamping rings.

Carbon steel turning parts for the clamping rings have zinc plated surfaces, the default being white zinc plating. For easy identification, the turning parts with thread holes are coated with yellow zinc plating.

The critical points for turning parts for the clamping rings control include the diameter tolerance of the arm area, the quality of the tread hole, and the burr around the thread hole tapping area. Although appearing simple, without the correct process and machines, quality issues can easily arise.

With 15 years of professional turning parts for the clamping rings production experience, Auwell has developed the most efficient way of producing such turning parts.

Следващото видео демонстрира производствения процес за струговане на части за Spannring:

В момента 100% от нашите стругови части за Spannring се изнасят в Германия за нашите уважавани клиенти. Използвайки оптимизирана технология и програмиране, нашите продукти са с отлично качество, като същевременно имат достъпна цена. Auwell се гордее с високата си производителност за производство на тези продукти по рентабилен начин.

The Turning Parts for Spannring products displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Технически спецификации

-Материал: ST12, ST37, Q235B, неръждаема стомана 304, 316L или при поискване

-Завъртащи части: Диаметър: Φ12mm с резба M6 илиΦ14mm с резба M6 или при поискване

-Surface treatment: zinc plating, or blanc for stainless steel

-Опаковка: найлонова торбичка, кашон, след това дървена кутия.

Предимства

-Rich Experience

More than 15 years of experience in this particular turning parts for clamping rings development and production, especially to the European markets. With solid understanding of the material, technical and quality standards worldwide.

-Бърз обрат

Generally, we provide a quotation within 2 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide turning parts for clamping rings samples in just a week.

-Comprehensive Solution Provider

Auwell предоставя цялостни услуги за струговане на части за проекти на затягащи пръстени, като се започне от проектирането, през прототипирането, вземането на проби, масовото производство и до логистичната и следпродажбената поддръжка.

-Твърди политики за контрол на качеството

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

За масово производство предлагаме гъвкави условия на плащане, ще бъдат дадени разумни условия за кредит, клиентът плаща само когато е доволен от продукта, който е получил. За дългосрочни проекти ние предлагаме услуги за инвентаризация на повикване за изисквания за бърза доставка.

Свързани продукти

Седло за затягащи пръстени

Седло за затягащи пръстени

Бърз конектор за затягащи пръстени

Бърз конектор за затягащи пръстени

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик